Circuit breakers are crucial elements in electrical systems; they serve as the guards against dangerous situations like overloads and short circuits. They operate by cutting off electrical current flow from a system when they sense that something is not normal and in turn prevent any damage to the circuitry, which greatly reduces risk of fires. Circuit breakers can be classified with respect to the following three types: miniatures, molded case circuit breaker and air insulated switchgear. All of these types have specific uses and are an important part in the electrical safety arena.

MCBs (Miniature Circuit Breakers)

Miniature circuit breakers - also known as MCBs for short, are the smallest of the trio and can be seen often in residential settings (homes) or smaller commercial buildings. Designed to protect low voltage circuits from excessive electricity. MCBs immediately cut the flow of electricity when an overload or a short circuit occurs. They work great for protecting circuits or outlets on their own, since they can be installed in a pretty small space.

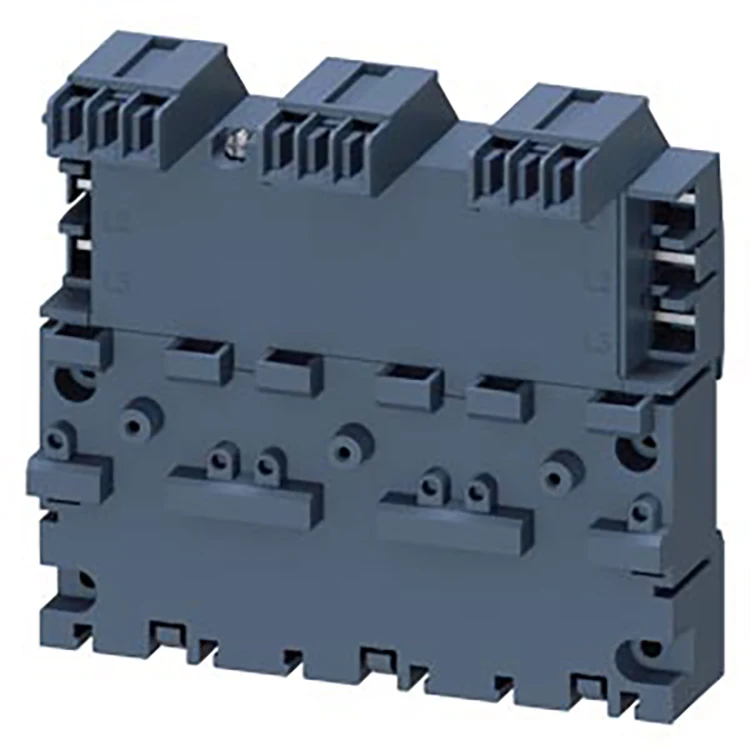

Molded Case Circuit Breaker ( MCCB ),

Whereas Molded Case Circuit Breakers, are larger and more complex devices that use an enclose case to handle bigger loads found in industrial or commercial installations. Finally, as specified by MCCBs provides settings that can be adjusted for protection to allow precise calibration according to the requirements of a given application. Thermal and magnetic overloads can be handled, with additional electronics options providing increased sensitivity and selectivity on some models. These durable lights are virtually indestructible in the toughest field environments with their impact-resistant molded thermoplastic case.

Air Circuit Breakers (ACBs)

These type of Air Circuit Breakers are used for high voltage and current application due to their ability[typically found in power plants or other heavy industrial applications. ACBs employ air for quenching the arc to interrupt high currents pronto in contrast with conventional circuit breakers. The breakers are equipped with advanced electronic systems that deliver rapid and accurate protection, such as ground fault detection or bundled function for more complex electrical networks.

Importance of Various Circuit Breaker Types

There is quite a range in all of these circuit breaker types showing the flexibility and diversity of modern electrical protection systems. Although miniature breakers work well for personal and small-scale use, molded case and air circuit breakers are the best choices to accommodate industrial setting constraints. This variety ensures that engineers and electricians have an accessible solution to the downside because they distribute current rating, interrupting capacity as well as environmental conditions for a comprehensive coverage of all electrical systems.

Matching breaker types with power needs

Miniature circuit breakers are suitable for low voltage distribution boards, and they can also be used in many places where there is not enough space which require standard protection from general-purpose functions. Molded case circuit breakers are used when higher breaking capacities or adjustable protection settings are needed, typically in motor control centers and transformer feeders. In power distribution systems, where reliability and resilience are essential, we couldn't do without air circuit breakers that can withstand huge fault currents.

How to Determine the Proper Circuit Breaker

Proper selection of the circuit breaker type is well suited to what the application needs. These MCBs are widely used for branch circuit protection in residential, offices and smaller retail spaces. These are more or less the high-voltage breakers and used to protect equipment in medium-size commercial/industrial systems that include motors, transformers and feeder circuits. These are used in extreme duty industries like heavy voltage, high vibration areas such places where air circuit breaker will not work correctly as an arc quenching medium.

How Does Thermal, Magnetic and Electronic Trip Circuits Works in Circuit Breakers

Circuit breaker operation relies heavily on the tripping mechanisms within:

Thermal Trip Devices-These are heat sensitive components that trip the breaker slowly as a result of prolonged overloads causing temperature to rise. Miniature Circuit Breaker(These type of breaker are used in mcb(fp) )

Magnetic trip devices on the other hand are designed to respond much faster and will tripped almost immediately with peak current surges seen during short circuits. When a short circuit occurs, excess current creates a magnetic filed that trips the mechanism, rapidly opening up the circuit. Molded case breakers frequently use the combination of both thermal and magnetic trip units to have similar comprehensive protection.

Electronics the promoogue to using electronic trip devices with Everlink? Advances,separation for MCCBs-(Circuit Breaker) and ACBs (Air Circuit breaker) that sequence use microprocessors in monitoring current over time. The technology holds the reins for trip setting precision, which in turn powers functions like selective coordination, ground fault detection and even predictive maintenance alerts. The whole point of electronic trip system is to provide quick response and more precise protection, that are essential in complicated electrical system.

Lastly a circuit breaker type which includes an over-current relay for tripping is one of the most important parameters to be considered along with its protective coordination in designing any electrical system. All three varieties — miniature, molded-case and air circuit breakers— have strengths that meet the needs of varying power demands as well as safety considerations. Knowledge of their unique characteristics and thermal, magnetic or electronic trip capabilities will allow professionals to choose the correct device for each application which in turn can reduce exposure resulting on a more efficient & safer power installation.

Table of Contents

- MCBs (Miniature Circuit Breakers)

- Molded Case Circuit Breaker ( MCCB ),

- Air Circuit Breakers (ACBs)

- Importance of Various Circuit Breaker Types

- Matching breaker types with power needs

- How to Determine the Proper Circuit Breaker

- How Does Thermal, Magnetic and Electronic Trip Circuits Works in Circuit Breakers

- Circuit breaker operation relies heavily on the tripping mechanisms within:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

%20(1)/images/share.png)