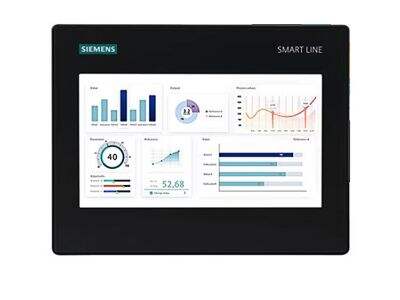

HMI (Human-Machine Interface) Dette er en smule jargon, men det er blot en måde for mennesker at kommunikere med og interagere med maskiner. Nogle hmi touch panel er faktisk computere, men et HMI-touchpanel er egentlig en grænseflade, der ligner at se en touch-screen på en computer. Operatorindtastning og vigtet maskinfeedback er mulige med dem. Det ville også betyde, at operatørerne kun skulle røre skærmen med deres fingre for at interagere med maskinen, hvilket gør den ekstremt brugervenlig.

Dette er fordi HYST HMI-touchpanele har ændret måden, hvorpå brugere kan arbejde, da de tillader meget nemmere maskinstyring. Tidligere var knapper og skiftere, der havde forårsaget masse forvirring og var ret abstrakte for operatører at forstå. Vel, i første omgang med et touch-HMI behøver operatøren ikke længere at trykke på en knap; nu bruger de bare deres finger og rører skærmen. Ved at gøre det muligt for maskinerne at følge deres opgaver hurtigere og mere effektivt, letter denne nye form for maskinhåndtering deres opgaver.

Fordele ved at bruge HMI-touchpanele

Der findes mange anvendelser af styringssystemer inden for produktion, olie og gas samt transport. Her bliver HMI-touchpanel til en virkelig ven for højteknologiske maskinoperatører, der arbejder i sådanne indirekte industrier med maskiner, da de kan styre maskiner på et mere sofistikeret måde (Kilde).

HMI-touchpanele har stor fortjeneste ved at vise live-data til operatørerne. Det gør det muligt for operatørerne at vide, hvad der sker med en maskine på ethvert tidspunkt. For eksempel kan de holde styr på vigtige detaljer som temperatur, tryk og hastighed. Det giver operatørerne data og information, som de behøver for at træffe bedre beslutninger om drift og kontrol af maskinen. De kan gribe ind, hvis noget går galt, og holde alt på skinner.

En anden primær fordel ved HMI-touchpaneler er, at de hjælper med at forebygge fejl. Touchkommandoer giver operatørerne mulighed for at vælge de korrekte indstillinger for en maskine. Dette er afgørende, da det minimerer fejl, der kan ødelegge maskinerne eller de varer, der produceres. Operatørkontroller, der er simple og lette at bruge, kan hjælpe operatørerne med at tilbringe mere tid på opgaver i stedet for at prøve at finde ud af, hvordan man bruger maskinerne.

At understøtte arbejdet: Fordele ved HMI-touchpaneler

Tid er i modsætning afgørende i industrielle opsætninger som fabrikker. Jo hurtigere maskinerne kan arbejde, jo mere præcise vil formen blive. Human-machine interface (HMI) touchpaneler moderniserer industrielle aktiviteter, da de sikrer, at operatørerne kan kontrollere maskinerne mere hurtigt og effektivt.

Et brugsscenario kunne være en produktionsskib, hvor operatørerne overvåger produktionslinjerne ved hjælp af industrielle hmi-touchpanel de kan overvåge status og justere indstillinger i alle tider, når det er nødvendigt. Dette reducerer nedetid, hvilket betyder en uafbrudt drift af maskinerne og dermed bistår i bedre produktivitet. Operatører kan også udnytte HMI-touchpaneler i olie- og gasanlæg til at overvåge rørledninger og brønner. Denne overvågning hjælper med at sikre, at der ikke opstår lekkager eller andre problemer, som enten ville ende for kostbare på grund af miljøproblemer eller, hvis alvorlige nok, kan blive farlige.

Hvordan hjælper HMI-touchpaneler operatørerne?

Forbedret evne til at kontrollere maskiner giver operatørerne mulighed for at afslutte deres opgaver hurtigere og mere præcist. Dette har betydning, da det hjælper dem med at udføre deres job bedre. HMI-touchpaneler bidrager også til at forbedre operatørernes effektivitet, da de gør det nemmere at kontrollere maskinerne.

For eksempel behøver operatører ikke at gå til forskellige maskiner og justere hver enkelt maskine individuelt, i stedet kan de med HMI-touchpaneler justere alle maskiner fra et centralt sted. Dette frigiver tid og undgår behovet for at gå igennem disse aktive områder under maskinadministrationen, hvilket er en sikker proces med færre muligheder for ulykker.

Grunde til implementering af HMI-touchskærme i industrien

Den industrielle type hmi touch panel giver adgang til en lang række fordele. Lad os starte med, at de vil give en forøgelse i effektivitet og produktivitet. En mere smidig drift af maskiner gør hele processen mere produktiv. Det betyder, at fabrikker kan producere flere produkter i mindre tid, hvilket ofte betyder højere overskud.

For det andet, eliminerer HMI-touchpanelerne fareren for ulykker og fejl. En reduktion i de muligheder, operatørerne har for at begå fejl, da de er i større kontrol med maskinen. I en industriell sammenhæng gør dette forskel, fordi en fejl betyder omkostninger - skader - eller farlige situationer.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

%20(1)/images/share.png)